AI is Turning Trash into Cashmere: A Deep Dive into the Tech Upending the $1.5 Trillion Fashion Industry

Everbloom is using AI to turn textile waste into high-performance, biodegradable fibers like cashmere—at a lower cost. Is this the solution to fashion's sustainability crisis?

The $50 Cashmere Sweater is a Lie. AI-Powered Alchemy is the Truth.

The fast-fashion industry sold consumers a convenient illusion: luxury materials like cashmere, once the domain of the elite, could be had for the price of a few lattes. But this affordability comes at a steep, hidden cost to the environment and animal welfare. Now, a material science startup named Everbloom is leveraging AI to expose that illusion and build a new reality. By transforming keratin-based waste into high-performance, biodegradable fibers, they're not just creating a cashmere substitute; they're creating a blueprint to dismantle the toxic economics of the entire textile industry.

Why This Matters More Than Just Another Eco-Fabric

This isn't another story about a niche, expensive, sustainable fabric. Everbloom's approach, powered by its Braid.AI platform, represents a fundamental paradigm shift because it tackles the three core barriers that have historically held back sustainable materials:

- The Cost Barrier: CEO Sim Gulati's stated goal is to make their upcycled materials cheaper than the originals. This rejection of the 'sustainable premium' is a direct assault on the business models of brands that rely on cheap, virgin, and often petroleum-based fibers.

- The Scale Barrier: Everbloom's process is designed as a "drop-in replacement," utilizing the same extrusion and spinning machinery that currently produces 80% of the world's textiles. This is a brilliant strategic move, bypassing the need for a multi-billion dollar infrastructure overhaul and dramatically lowering the barrier to adoption for manufacturers.

- The Performance Barrier: Consumers won't adopt sustainable alternatives if they don't perform. Braid.AI's ability to fine-tune fiber characteristics aims to replicate—and potentially exceed—the qualities of materials like cashmere or polyester, removing the need for compromise.

The Analysis: Deconstructing Everbloom's Playbook

From Waste Stream to Value Chain

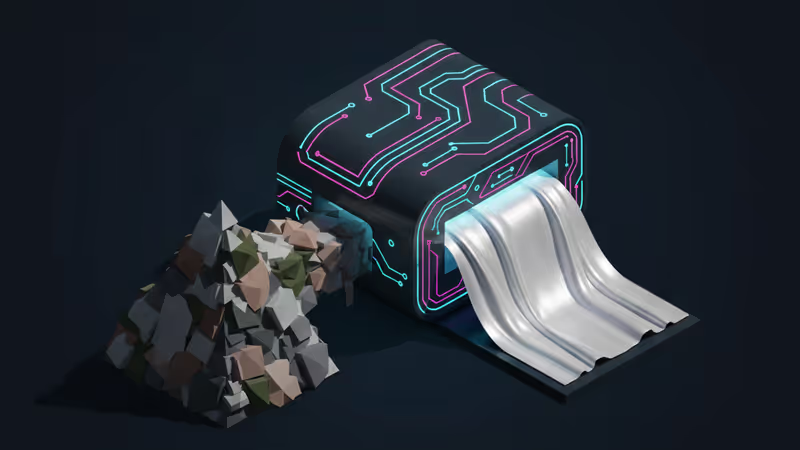

At its core, Everbloom is an industrial alchemist. The company targets keratin—the protein found in waste from cashmere farms, wool mills, and even the poultry industry—as its base element. This feedstock is abundant, perpetually generated, and currently treated as a low-value byproduct or waste. Braid.AI acts as the 'philosopher's stone,' precisely controlling chemical formulations and machine parameters to transmute this waste into consistent, high-quality fibers. This moves the source of value from unpredictable agricultural outputs to predictable industrial processes.

The Real Disruptor Isn't the Fiber, It's the 'Drop-In' Strategy

The history of material science is littered with promising innovations that failed to achieve mass adoption. Think of early-stage lab-grown fabrics or complex bio-materials that required entirely new manufacturing equipment. These ventures failed because they asked the gargantuan, capital-intensive textile industry to change its ways. Everbloom's decision to work with existing infrastructure is the most critical and overlooked aspect of its strategy. It allows them to pitch textile mills not on a revolution, but on a simple input swap: use our sustainable, cost-effective pellets instead of your current ones. This dramatically reduces friction and accelerates the path to scale.

PRISM Insight: The Investor and Industry Readout

For Investors: This is an AI Platform Play, Not a Fashion Play

Venture capitalists backing Everbloom with over $8 million aren't just betting on eco-friendly sweaters. The real investment thesis is in Braid.AI as a material science platform. The ability to digitally model and then physically produce novel materials with specific properties (softness, durability, biodegradability) on demand is the holy grail. The Total Addressable Market (TAM) isn't just the cashmere market; it's a slice of the entire $700 billion global synthetic fiber market. The primary risk isn't technological, but logistical: can Everbloom secure and scale a consistent, clean supply chain for its keratin-based waste feedstock globally? Solving this reverse logistics puzzle is key to their long-term moat.

For Brands: The End of Supply Chain Volatility?

For brands from Zara to Kering, Everbloom offers a tantalizing proposition: an escape from volatile commodity markets and a solution to mounting ESG pressure. A brand's reliance on cashmere, for example, is subject to climate change affecting pastures, geopolitical risks, and animal welfare scandals. A drop-in, cost-competitive, and ethically sound alternative like Everbloom's fiber de-risks the supply chain. The first major brand to sign a large-scale offtake agreement with a company like this won't just get a PR win; they will gain a significant, structural cost and supply advantage over competitors.

PRISM's Take

Everbloom is a leading indicator of a profound shift where AI moves from the digital world of bits and bytes to manipulate the physical world of atoms and molecules. While the promise of biodegradable, high-performance fibers from waste is immense, the company's true genius lies in its pragmatism. By targeting cost-parity and designing for the industry's existing infrastructure, they are bypassing the 'green ghetto' of premium-priced niche products and aiming directly for the industrial mainstream.

This is the model for future climate tech success: don't just invent a better product, invent a better business model that makes the sustainable choice the easy and profitable choice for everyone. If Everbloom can solve its waste-sourcing logistics at a global scale, it won't just be a successful startup; it will become the 'Intel Inside' for a new generation of sustainable, circular manufacturing.

Related Articles

Everbloom's AI turns waste into biodegradable cashmere that's cheaper than virgin materials. Is this the end of fast fashion's unsustainable model?

A startup's AI is turning waste into high-performance textiles like cashmere. Discover how this could upend the fashion industry and make sustainability cheaper.

A startup's AI is turning waste into high-performance textiles like cashmere. Discover how this could upend the fashion industry and make sustainability cheaper.

A multi-state lawsuit against Uber's subscription practices isn't just about ride-sharing. It's a regulatory attack on the 'dark patterns' that power the tech economy.