Printing Ice at Room Temperature: The Physics Breakthrough Redefining Manufacturing

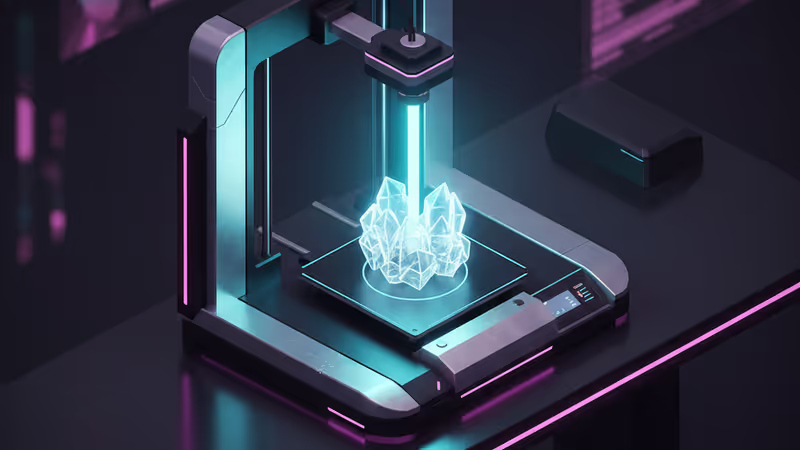

Physicists 3D-print ice at room temperature, unlocking a new paradigm in energy-free microfabrication with implications for medicine and manufacturing.

The Lede: Beyond the Novelty

While the image of a tiny, 3D-printed ice Christmas tree is a clever bit of holiday science, leaders in technology and manufacturing should look past the ornament and focus on the unprecedented process behind it. Physicists at the University of Amsterdam have demonstrated a method for 3D printing with water at room temperature, without any refrigeration. This isn't just a party trick; it's a proof-of-concept for a new class of fabrication technology—one that uses fundamental physics to build temporary, complex structures with minimal energy. This represents a paradigm shift from brute-force cooling to precision thermal management, a capability with profound implications for everything from biotech to microelectronics.

Why It Matters: The End of Brute-Force Cooling?

For decades, creating frozen structures has required one thing: an energy-intensive refrigerator. This University of Amsterdam experiment completely sidesteps that requirement, leveraging a phenomenon known as evaporative cooling. By precisely controlling the evaporation of a specialized mixture of water and other particles, the researchers can induce rapid, localized freezing. This matters because it decouples solidification from ambient temperature, unlocking a host of second-order effects:

- Biomedical & Surgical Tech: Imagine creating temporary, biocompatible scaffolds or guides for surgery inside the body. An ice-based structure could provide support during a procedure and then simply melt away harmlessly, eliminating the need for a second removal surgery.

- Microfluidics & Lab-on-a-Chip: This technique could be used to create temporary micro-valves or channels within a fluidic device. A circuit could be reconfigured on the fly by printing and melting ice barriers, enabling more dynamic and complex experiments.

- Advanced Manufacturing: The process is perfect for creating sacrificial molds. A complex ice mold could be printed, cast with another material, and then simply washed away with water, leaving a perfect replica without the harsh chemicals or high temperatures often needed to remove traditional molds.

The Analysis: From BBQ Stalls to Bose-Einstein Condensates

The science here, evaporative cooling, is deceptively common. It’s why you feel cold after a swim, why sweating cools you down, and, as the source article notes, it’s the culprit behind the dreaded “stall” in barbecue where the meat’s temperature plateaus. In all cases, the most energetic (hottest) water molecules escape as vapor, lowering the average energy—and thus the temperature—of the molecules left behind.

What’s brilliant here is not the discovery of the phenomenon, but its precise, weaponized application. This is the same principle physicists use to cool atoms to near absolute zero to create Bose-Einstein condensates, a state of matter where quantum effects become visible on a macro scale. By applying this high-concept physics to the everyday process of 3D printing, the researchers have created a new tool. Unlike conventional 3D printing which adds energy (via lasers or heat) to cure a material, this method removes energy with surgical precision. This is a fundamental inversion of the typical additive manufacturing process, opening a design space previously limited by the laws of thermodynamics in a standard environment.

PRISM Insight: The Rise of Thermodynamic Manufacturing

This experiment is a leading indicator of a broader trend we call Thermodynamic Manufacturing. The next frontier of innovation isn't just in discovering new materials, but in developing novel, low-energy processes to manipulate the state of existing ones (solid, liquid, gas). Investors and R&D leaders should be looking for platforms that use fundamental physics—like evaporative cooling, sonocrystallization, or acoustic levitation—to control material properties at the micro-level. The competitive advantage will shift from those who have the best materials to those who have the most precise and energy-efficient control over phase transitions. This is the ultimate in sustainable, ephemeral, and intelligent fabrication.

PRISM's Take:

The 8-centimeter ice tree is a symbol, not the story. The story is that we are learning to command the physical state of matter with finesse rather than force. Forcing a material to be cold by putting it in a massive, energy-hungry freezer is a tool of the 20th century. Inducing localized, pinpoint freezing through the controlled physics of evaporation is a 21st-century capability. It’s a move from sledgehammer to scalpel. This research signals the dawn of on-demand, temporary, and environmentally benign manufacturing, where the structures we build can disappear as easily as they are created, leaving nothing behind but water.

Related Articles

OpenAI's new AI literacy guide is more than a safety manual; it's a strategic move to normalize AI, pre-empt regulation, and secure future market dominance.

OpenAI's new teen safety rules are more than a feature. It's a strategic move to redefine responsible AI, setting a new standard for Google and the industry.

China's LightGen optical chip claims 100x+ gains over Nvidia. Is this a lab curiosity or China's strategic answer to crippling US tech sanctions?

OpenAI's framework for monitoring AI's chain-of-thought is a strategic move to solve the 'black box' problem, setting a new standard for AI safety and control.